By Rapid Turn Laser & Machine – Houston, Texas

In modern manufacturing, accuracy doesn’t live in the “nice to have” category anymore — it’s fundamental. Every industry that relies on metal fabrication, from aerospace to heavy equipment, needs parts that don’t just look right but measure right. That’s where tight tolerances enter the picture. They turn a cut piece of metal into a true, dependable component.

Still, tolerances are one of the most misunderstood aspects of engineering drawings. Designers request them, machinists chase them, inspectors verify them, and procurement sometimes wonders why they influence cost so dramatically. This article removes the confusion and explains why tight tolerances matter, when they matter, and how the right fabrication partner makes all the difference.

Understanding Machining Tolerances

Every part begins with a nominal dimension — the ideal measurement. But in the real world, nothing is produced to mathematical perfection. Tolerances define how much deviation is acceptable. They act as a contract between the designer and the manufacturer, spelling out the limits within which the part must fall to function correctly.

Consider a half-inch hole specified as 0.500 inches. That number alone doesn’t tell you whether a hole at 0.498 or 0.503 inches is acceptable. When the drawing adds ±0.005, it suddenly becomes clear that anything between 0.495 and 0.505 inches passes inspection. Tighten that to ±0.001, and now the acceptable window shrinks to the width of a human hair.

Tolerances affect whether parts fit together smoothly, whether assemblies behave predictably, and whether components survive real-world stress. Without them, manufacturing becomes guesswork — and nobody wants guesswork in a jet engine, medical device, or high-speed automation line.

The Different Ways We Define Precision

Although most people think of tolerance strictly as a “plus or minus” dimension, the machining world uses multiple types of tolerances depending on what the part requires.

Linear tolerances apply to straight-line measurements such as length, width, height, or hole diameter. These are the most common and give manufacturers a clear numeric range to meet.

Angular tolerances control the accuracy of angled features like mitered edges or bent components. When a design depends on two pieces aligning cleanly, angular precision becomes essential.

Then there’s the powerful, sometimes intimidating field of Geometric Dimensioning and Tolerancing (GD&T). GD&T communicates how a part must behave in three-dimensional space rather than just what size it should be. It handles things like flatness, parallelism, perpendicularity, true position, runout, and concentricity — all of which influence how a part fits, moves, seals, or rotates.

Finally, designers sometimes specify tolerances based on the type of fit needed between mating parts. Whether a shaft should glide inside a bearing, slide in with a little persuasion, or require a press fit, the tolerance determines whether the assembly performs as intended.

Together, these different tolerance styles create a full picture of what the part must do — not just what it must measure.

What the Industry Calls “Tight Tolerance”

Different industries define tight tolerances according to their needs, but some general ranges help establish expectations. Standard machining typically sits around ±0.010 inches. High-quality fabrication shops like Rapid Turn routinely work in the ±0.005–0.001 range, depending on geometry and material. When tolerances dip into ±0.0005 or smaller, you’ve entered the realm of ultra-precision — a place dominated by aerospace and medical technology.

Tighter tolerances require more care, better machines, and more inspection. They represent a commitment to performance that standard fabrication simply can’t match.

| Tolerance Range | Classification |

|---|---|

| ±0.010 in (0.254 mm) | Standard machining |

| ±0.005 in (0.127 mm) | Precision machining |

| ±0.001–0.002 in (0.025–0.050 mm) | Tight tolerance |

| ±0.0005 in or below (0.012 mm or below) | Ultra-precision aerospace/medical |

Why Material Choice Changes Everything

Different metals behave differently under machining forces. Some resist heat, some expand easily, some gum up tooling, and some hold dimensional stability effortlessly. This natural behavior influences how tight a tolerance can be held.

Aluminum, for example, machines beautifully and responds well to tight tolerances, but it expands noticeably with heat. Stainless steel offers strength and corrosion resistance but generates heat during cutting, which increases the difficulty of maintaining extremely small tolerances. Carbon steel strikes a balance, holding tolerances well while keeping costs manageable. Brass and copper excel in precision applications thanks to their dimensional stability and smooth machining characteristics.

Even sheet metal introduces variables. A laser can cut with incredible accuracy, but the flatness of the raw sheet determines how well a large part will retain its true dimensions. A good fabricator understands these subtleties and compensates for them during production.

How Fiber Laser Cutting Supports Precision

Modern fiber lasers have transformed the precision landscape. Their ability to focus intense energy into a narrow kerf produces clean, consistent cuts with minimal heat-affected zones. For thin and medium gauge metal, this technology offers impressive accuracy and repeatability.

Because a fiber laser imposes less thermal distortion than older methods, it creates parts that behave predictably in downstream processes like bending, welding, and CNC machining. When you combine laser cutting with precision machining — a common workflow at Rapid Turn — you get parts that meet strict specifications without unnecessary rework.

Why Tight Tolerances Matter in Real Applications

Tolerances are more than numbers in a title block; they’re the quiet guardians of safety, performance, and longevity.

In the aerospace industry, tolerances determine whether components handle extreme pressure changes, temperature swings, and high vibration without failure. A misaligned hinge or an imperfect bracket isn’t just an inconvenience — it’s a risk.

The automotive sector relies on precision to eliminate vibration, reduce noise, improve fuel efficiency, and extend the lifespan of moving components. Even a small misalignment can multiply wear across an entire system.

In oil and gas, particularly in Houston’s industrial ecosystem, reliable tolerances ensure seal integrity, structural strength, and pressure containment. Precision becomes essential when equipment routinely faces high temperatures, corrosion, or extreme mechanical stress.

The medical field demands near-perfect dimensional accuracy, because patient safety leaves no room for guesswork. Tolerances here can make the difference between a device that performs flawlessly and one that introduces risk.

And in robotics and industrial automation, predictable motion depends on parts manufactured with consistency. Precision ensures smooth travel, accurate sensing, and reliable operation.

Across all these industries, tight tolerances directly influence cost of failure — and cost of failure is always higher than cost of precision.

Why Tighter Tolerances Increase Manufacturing Cost

If you’ve ever wondered why machining cost jumps when the tolerance tightens, the reason has nothing to do with a fabricator “up-charging” and everything to do with physics, tooling, and time.

A machine can reach a tolerance of ±0.005 inches fairly quickly. But as soon as the tolerance narrows to ±0.001 inches, the entire machining process slows down. Feed rates drop, toolpaths become more sophisticated, the shop must use higher-grade tools, and the chance of scrap increases. Inspection becomes more extensive, often involving micrometers, height gauges, optical comparators, or CMMs.

Reaching extremely tight tolerances also requires perfect fixturing, greater thermal stability, and sometimes even a climate-controlled environment to avoid temperature-induced expansion.

In short, the smaller the tolerance window, the more effort required to land inside it — consistently, not just once.

The Importance of ISO 9001 Certification

Quality doesn’t happen by accident. ISO 9001 certification proves that a shop follows disciplined, repeatable processes designed to maintain accuracy from the first part to the last.

Rapid Turn Laser & Machine’s ISO 9001:2015 certification means dimensional accuracy isn’t just something we aim for; it’s something we document, measure, and prove. Our quality workflow includes first-article inspections, in-process monitoring, calibrated measuring tools, traceability of materials, and a structured final quality checkpoint before parts ship.

A certified system safeguards consistency, which is essential when working at the tolerance levels many industries demand.

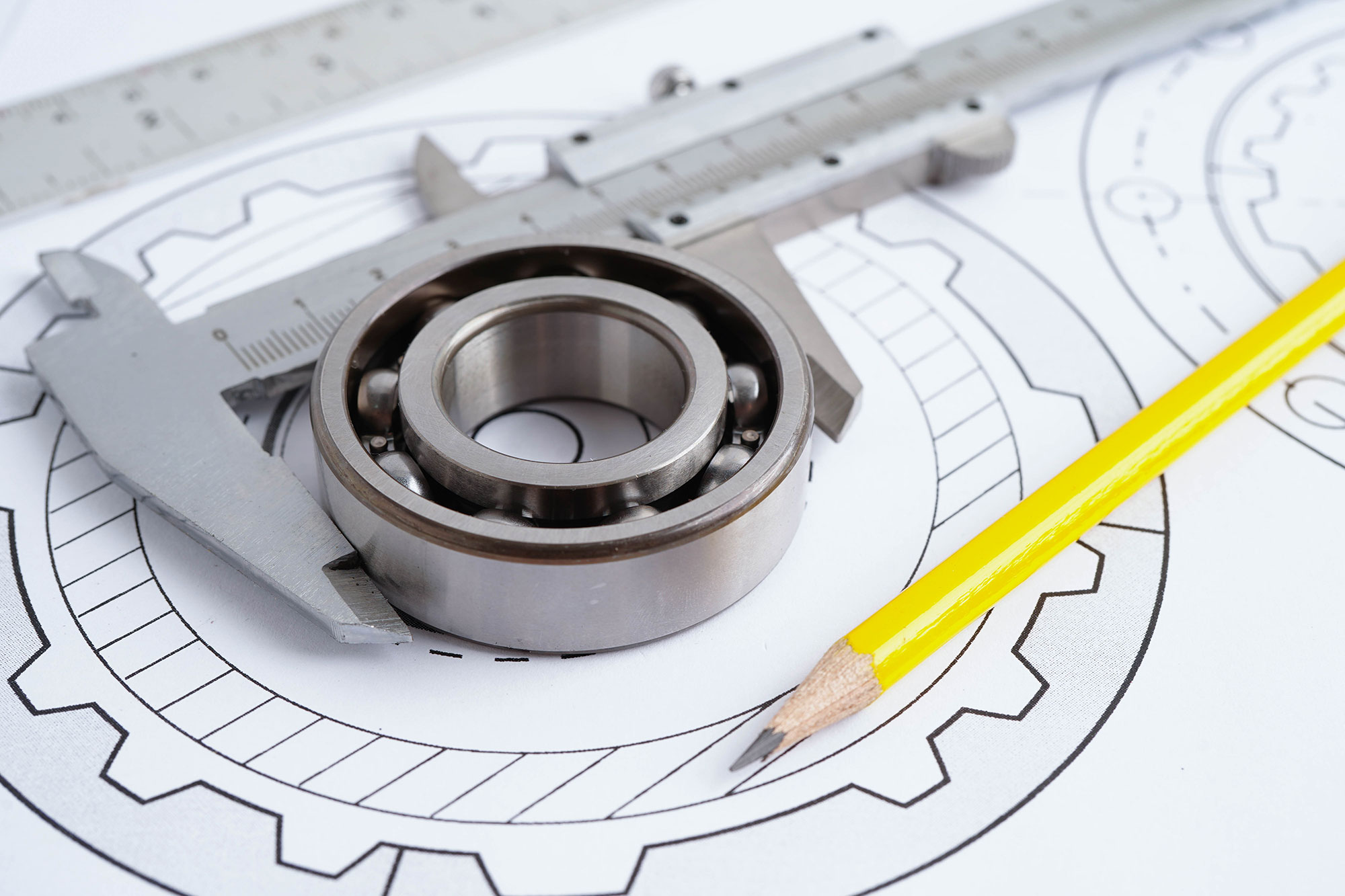

How Precision Is Measured

Because tolerances vary so widely, inspection requires the right tool for each job. Basic digital calipers handle everyday checks, but truly tight tolerances demand more advanced instruments.

Micrometers measure down to ten-thousandths of an inch, giving inspectors the confidence needed when tolerances are razor thin. Height gauges and surface plates provide a stable foundation for measuring flatness, squareness, and step features. For complex GD&T callouts, a coordinate measuring machine (CMM) verifies positional accuracy in three dimensions. Laser inspection systems offer an even higher level of precision when required.

Inspection isn’t the end of the manufacturing process — it’s woven throughout it. The tighter the tolerance, the more often the part needs to be checked.

Choosing the Right Fabrication Partner

Every machine shop can claim to produce “precision parts,” but fewer can prove it. Precision comes from experience, equipment, training, and the discipline to follow structured procedures every single time.

A reliable precision manufacturer invests in high-end CNC machines, modern fiber lasers, advanced tooling, and trained operators. They understand GD&T, communicate clearly, and identify potential design issues before production begins. They move quickly when timelines demand it but never cut corners on quality.

Rapid Turn Laser & Machine stands apart because we combine speed with precision. Many shops offer one or the other. We built our business around delivering both — consistently, reliably, and at a level of service that keeps our customers returning project after project.

When Tight Tolerances Are Essential — and When They’re Not

Not every feature of a part needs to be controlled with extreme precision. In fact, over-tolerancing is one of the leading causes of unnecessary manufacturing expense.

Tight tolerances matter most when a part must fit, seal, move, or align with another part. They matter when the part will experience high load, extreme temperatures, or safety-related stress. They matter in assemblies where one inaccurate part could compromise the entire mechanism.

But there are areas where tolerances can be relaxed without harming performance. Cosmetic features, large flat surfaces, and non-critical edges don’t usually benefit from extreme precision. Prototypes sometimes need speed more than perfection, and simplifying tolerances can accelerate development.

An experienced fabricator helps you strike the right balance — tightening where precision boosts performance and loosening where it cuts cost without affecting functionality.

How Rapid Turn Laser Helps You Hit the Right Tolerances

When customers send drawings, our engineers evaluate them not as static documents but as roadmaps. We study the material, geometry, critical features, and end-use environment. We consider how the part will behave when cut, bent, welded, or machined. We check for unnecessary tight tolerances, missing callouts, or features that require clarification.

We don’t just manufacture parts — we advise on manufacturability. When we see opportunities to improve performance or reduce cost, we flag them early. When a tolerance needs tightening to ensure proper fit, we identify it before production. When a feature could compromise bend accuracy or weld strength, we let you know before it becomes a problem.

This collaboration saves time, prevents rework, reduces scrap, and produces parts that work exactly as intended.

Final Thoughts: Precision Defines Quality

Precision machining isn’t about chasing numbers for the sake of it. It’s about ensuring that the parts you rely on perform exactly as designed — every time they’re put into service. Tight tolerances protect fit, function, longevity, and safety. They safeguard your assembly line, your customers, and ultimately your reputation.

At Rapid Turn Laser & Machine, precision is a culture, not a buzzword. We combine ISO-certified processes, advanced technology, and skilled machinists to deliver accuracy you can measure and reliability you can trust.

If you need a partner who understands why tight tolerances matter — and who can help you meet them without unnecessary cost — we’re ready when you are.